Understanding BRC Global Standards for Food Contact Materials

What Is BRCGS Packaging & A+ and Why It Matters for Food-Safe Packaging

The BRCGS Packaging & A+ certification comes from the British Retail Consortium and has become a gold standard for food safe packaging around the world. What makes this certification important? It covers three main areas: keeping things clean, making sure materials don't harm food, and having good quality control systems in place. Products need to pass pretty tough tests before they can touch food directly. Biodegradable dinnerware companies really need to get this certification if they want to sell their products widely. Most big stores won't even consider working with them without it. According to recent data, about 89 out of 100 global retailers require this kind of certification these days as shown in the latest Food Safety Report.

The framework mandates hazard analysis, traceability, and contamination controls, making it essential for suppliers targeting markets in the EU, US, and Asia.

Application of BRC Standards to Biodegradable Dinnerware Materials

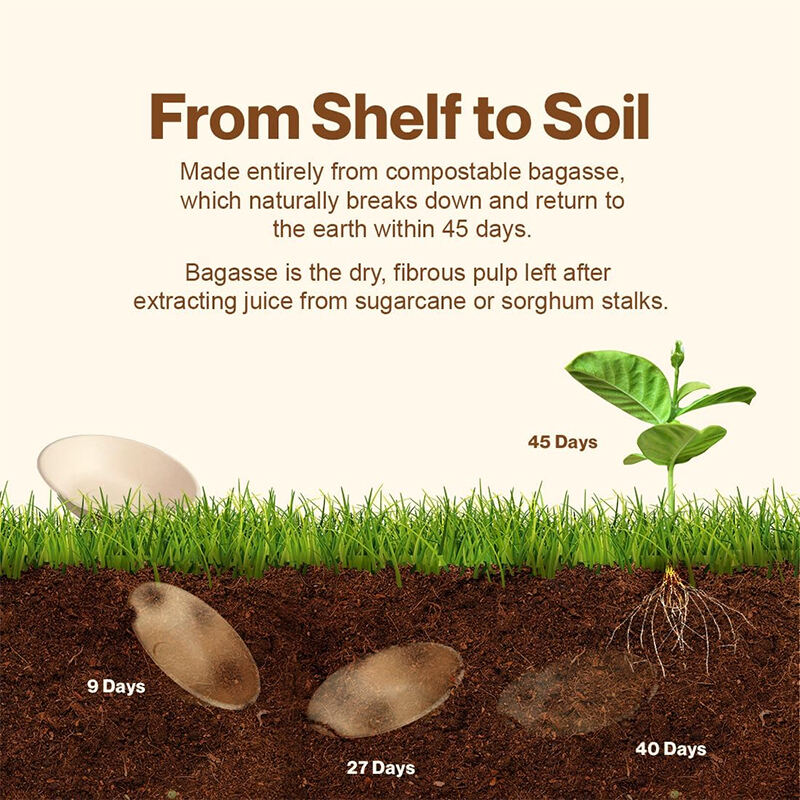

BRC standards require biodegradable materials like PLA, palm leaf, or bagasse to undergo rigorous migration testing to verify chemical inertness under typical food-use conditions. Manufacturers must ensure compostable plates maintain structural integrity without leaching harmful substances such as phthalates or heavy metals.

For example, BRCGS Appendix 8 specifies permissible microbial growth limits (±1,000 CFU/g) in plant-based dinnerware, confirming that compostability claims do not compromise food safety. Over 70% of facilities certified under the BRC IoP Standard for Packaging Materials report improved raw material traceability—critical when sourcing bioplastics.

Regulatory Expectations for BRC-Compliant Food Contact Products

Regulators in key markets require disposable dinnerware to meet BRCGS chemical migration thresholds, including:

| Substance | EU Limit (mg/kg) | BRCGS Tolerance |

|---|---|---|

| Lead | 0.2 | 0.1 |

| Formaldehyde | 15 | 10 |

Annual third-party audits under Clause 3.5.1 verify ongoing compliance, with non-conforming products facing a 97% recall rate in 2023. Unlike biodegradability certifications (e.g., ASTM D6400), the BRCGS framework prioritizes hazard prevention through validated sterilization protocols and supplier approval systems—a distinction manufacturers must consider when marketing eco-friendly tableware.

BRC Certification Process for Biodegradable Dinnerware Manufacturers

Core Requirements for BRC Food Safety and Quality Management Systems

Manufacturers who want their biodegradable dinnerware certified by BRCGS need to put in place what's called a HACCP system. This helps them deal with all sorts of potential problems like bacteria growth, chemical residues, and foreign objects getting into products during production. The requirements come straight from BRC Global Standards Issue 9, which basically says companies have to document everything related to quality management, create proper procedures for handling allergens, and keep track of where every batch goes through the supply chain. Factory floors also need designated clean areas and records showing workers get regular safety training. Looking at numbers from the BRC Annual Report for 2023, most places that followed these rules saw around a 40% drop in contamination cases after just two years of operation under this framework.

Steps in the BRCGS Certification Process: From Documentation to Audit

The certification journey involves three phases:

- Pre-Audit Gap Analysis: Auditors review material safety data sheets and manufacturing workflows.

- Stage 1 & 2 Audits: Facility inspections verify compliance with food-grade material handling and waste disposal protocols.

-

Certification Grant: Successful manufacturers receive a BRCGS mark valid for 12 months.

A 2023 industry survey found that manufacturers following the BRCGS certification process achieved certification 30% faster than those relying on informal systems.

Compliance Verification: Audits, Corrective Actions, and Recertification

Annual unannounced audits ensure sustained compliance, with any non-conformities requiring root-cause analysis and corrective actions. For instance, 67% of biodegradable plate producers resolved packaging defects within 14 days post-audit to avoid decertification (Food Safety Magazine 2024).

Addressing the Gap: BRC’s Focus on Safety vs. Biodegradability Claims

While BRC standards prioritize food safety, they do not validate biodegradability timelines or compostability. Manufacturers must supplement BRC certification with ASTM D6400 or EN 13432 testing to substantiate environmental claims—a dual-compliance strategy adopted by 58% of export-ready suppliers (EcoPackaging Insights 2023).

Food Safety Requirements Under BRC and Their Impact on Disposable Plate Design

How BRC Food Safety Norms Shape Manufacturing Practices for Biodegradable Dinnerware

Manufacturers who have BRC certification put HACCP systems into place so they can spot potential problems when sourcing raw materials and during production processes. The facilities themselves need to stick to certain design rules set out by BRC, including separate areas where biodegradable stuff like PLA or bagasse is handled to stop any mixing between different materials. Every three months, these production lines get checked for material integrity, something that ties back to specific parts of the BRCGS standard, particularly sections dealing with hygiene practices and process validation requirements. Training sessions for staff members focusing on allergens have made a real difference too. Workers now know the difference between cornstarch and wheat products, which has cut down on food safety issues at certified plants by around 73 percent according to research published in the Food Safety Journal last year.

Migration Testing and Chemical Safety Compliance for Compostable Tableware

BRC certified disposable plates must go through migration tests according to EU Regulation 10/2011 so that harmful stuff like phthalates or PFAS doesn't end up in our food. Independent laboratories run these tests on materials heated to around 70 degrees Celsius or about 158 Fahrenheit, which is pretty much what happens when someone serves something hot on them. The rules set by BRC regarding chemicals demand complete transparency about ingredients used, and this has actually pushed most manufacturers toward switching their coatings from petroleum based products to ones made from plants since early last year. When batches fail to meet standards they get locked away right away as per clause 7.4.2 of the regulations. No wonder then that nearly 8 out of 10 restaurants across America have started going for disposables labeled with the BRC mark nowadays.

Preventing Microbial Contamination in BRC-Certified Production Facilities

Manufacturers of biodegradable dinnerware typically follow ISO 14644 Class 8 cleanroom guidelines, keeping humidity levels under 35% to stop mold growth in their starch-based products. The air gets filtered through these systems anywhere from 20 to 30 times every hour, which cuts down on airborne germs by nearly 90% according to research published in the Journal of Food Protection last year. They also do regular swabbing of surfaces throughout the day and run all finished bamboo fiber plates through UV-C treatments after production. This helps them stay within strict microbial limits around 10 colony forming units per gram at most. Such rigorous standards matter a lot for medical facilities and commercial aviation where disposable items need to be completely free from pathogens.

Key Metrics: Disintegration, Toxicity, and Timeframe in Biodegradable Product Standards

Biodegradable dinnerware must meet three core metrics for global certification:

- Disintegration: ≥90% breakdown within 12 weeks (per EN 13432)

- Toxicity: Heavy metals ±50% of regulatory limits and no adverse soil impact

- Timeframe: Full biodegradation within 180 days under industrial composting

For example, OK Compost certification requires complete decomposition within six months without toxic residues, ensuring materials return harmlessly to ecosystems.

Comparing Biodegradability Regulations in the EU, US, and Australia

Divergent regional standards create challenges for exporters:

| Region | Key Standard | Disintegration Time | Testing Scope |

|---|---|---|---|

| EU | EN 13432 | 12 weeks | Industrial compost |

| US | ASTM D6400 | 180 days | Commercial facilities |

| Australia | AS 5810 | 24 weeks | Home compost |

The EU focuses on industrial composting, while Australia’s AS 5810 certifies home compostability, and the US allows longer timelines for commercial operations. Manufacturers often reformulate materials to meet multiple standards.

Aligning BRC Certification with Environmental Labels Like OK Compost and ASTM D6400

BRC Global Standards focus on food safety but complement ecological certifications:

- Food Safety: BRC ensures materials prevent chemical migration (e.g., PFAS <0.1 ppm).

- Compostability: OK Compost or ASTM D6400 validate biodegradability.

Leading suppliers now pursue dual certification—such as BRCGS Packaging + OK Compost—to meet retail demands for both safety and sustainability.

Resolving the Industry Paradox: High Food Safety vs. Inconsistent Eco-Certifications

Manufacturers constantly struggle when trying to meet both BRC's strict hygiene requirements and the patchwork of compostability standards out there. They have to pick their battles most days. But things might be changing soon. The European Union rolled out its Circular Economy Action Plan in 2023, aiming to bring together food safety rules and compostability tests under one roof. This suggests we'll see some real progress on this front eventually. For companies exporting products, getting ahead of the curve makes sense. Start working with EN 13432's toxicity thresholds now and get familiar with ISO 18606 for home compostability. These standards will help fill the current gaps between different regulations across borders.

Table of Contents

- Understanding BRC Global Standards for Food Contact Materials

- BRC Certification Process for Biodegradable Dinnerware Manufacturers

-

Food Safety Requirements Under BRC and Their Impact on Disposable Plate Design

- How BRC Food Safety Norms Shape Manufacturing Practices for Biodegradable Dinnerware

- Migration Testing and Chemical Safety Compliance for Compostable Tableware

- Preventing Microbial Contamination in BRC-Certified Production Facilities

- Key Metrics: Disintegration, Toxicity, and Timeframe in Biodegradable Product Standards

- Comparing Biodegradability Regulations in the EU, US, and Australia

- Aligning BRC Certification with Environmental Labels Like OK Compost and ASTM D6400

- Resolving the Industry Paradox: High Food Safety vs. Inconsistent Eco-Certifications