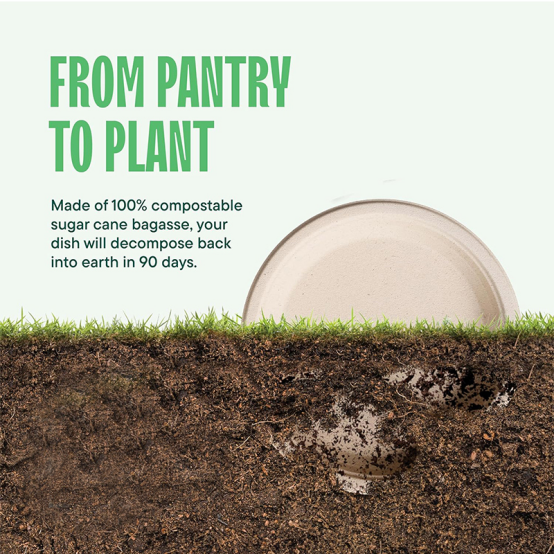

Bagasse turns what would otherwise be agricultural trash into strong food packaging materials. Every year around 800 million metric tons of sugarcane fiber gets thrown away when they process sugar, according to recent environmental reports. What makes this stuff special is how it stands up against grease and wetness all on its own, no chemicals needed, which explains why so many companies now make clamshell containers from it. Plastic just can't compete here because regular plastic takes forever to break down. Bagasse? It disappears in about two to three months if tossed into an industrial composter. Researchers have looked at this stuff extensively too, running tests on different plant based materials to see how they hold up over time.

Industrial Composting Requirements for Bagasse Biodegradable Clamshell Breakdown

For bagasse to decompose properly, it needs pretty consistent heat around 140 to 160 degrees Fahrenheit plus specific microbes that are typically only available at industrial composting sites. Industrial systems can actually break down the tough cellulose in bagasse pretty well, turning it into good quality compost in about the time it takes for one growing season. The problem? Around 70 percent of cities across America don't have these kinds of facilities nearby. That means even though bagasse is naturally compostable, most communities can't take full advantage of its environmental potential because they simply don't have access to proper composting infrastructure.

Certifications Matter: EN13432 and ASTM D6400 Compliance for Compostable Food Containers

Third-party certifications validate real-world performance:

- EN13432: Requires 90% biodegradation within 12 weeks in industrial compost

- ASTM D6400: Ensures non-toxic decomposition without heavy metal residues

Manufacturers passing these tests guarantee clamshells won’t contaminate compost streams or persist in landfills like traditional plastics.

Performance with Hot, Greasy, and Moist Fast Foods

Heat and Moisture Resistance of Bagasse Clamshells in Real Fast Food Conditions

Bagasse biodegradable clamshells resist moisture and steam from hot foods like burgers or fries, maintaining their shape for up to 2 hours at temperatures exceeding 160°F (71°C). Unlike starch-based containers that soften quickly, bagasse’s fibrous composition prevents sogginess—making it well-suited for saucy wings or steamed dumplings.

Oil and Leak Resistance When Holding Fried or Saucy Menu Items

What really works against grease leakage is this thick layer of fibers that acts as a built-in shield. Tests show these containers resist oil much better than regular paper ones, probably around 68% improvement if memory serves right from those lab results. That's why they work so well for greasy foods we all love, think chicken strips or nachos covered in melty cheese. When someone needs to keep food fresh longer than four hours though, many companies throw in a compostable PLA liner inside. It stops any mess from happening, and honestly this extra layer has become pretty standard stuff now across most big scale clamshell packaging in the market.

Structural Integrity During Transport and Delivery: Latch Security and Durability

Reinforced snap-lock latches maintain over 90% closure integrity during 30-minute delivery cycles, reducing spill risks compared to foldable cardboard boxes. Their rigidity supports vertical stacking of up to six units, offering logistical advantages for drive-thru efficiency and space optimization.

Microwave Safety and Thermal Performance Compared to Plastic

Can Bagasse Biodegradable Clamshell Containers Be Reheated Safely?

Containers made from bagasse that meet food grade standards such as ASTM D6400 have been officially marked as safe for use in microwaves. Research indicates these containers can handle heat reaching around 220 degrees Fahrenheit without bending shape or releasing anything bad into food, which means they work pretty well when someone wants to warm up leftovers like those greasy burgers or crispy fries from last night's dinner. According to a study published in 2025 looking at how different materials hold up over time, bagasse actually does better than both regular paper products and Styrofoam when it comes to staying stable under heat. These containers keep their form even after sitting in a microwave for about two minutes straight.

Thermal Stability: How Bagasse Performs Versus Plastic and Foam at High Temperatures

Polystyrene foam starts to soften when temperatures hit around 165 degrees Fahrenheit, and thin plastics just melt away completely. Bagasse products hold their shape even when exposed to high heat though. That means fried chicken can stay crispy for over half an hour without getting soggy. Plus, the material resists oil buildup so it doesn't collapse or deform. What's really nice about bagasse is those natural plant fibers let steam escape properly. No more dealing with that gross sogginess that happens when food sits under airtight plastic covers all day long trapping moisture inside.

PFAS Free Assurance and Taste Neutrality in Food-Grade Bagasse Packaging

Leading manufacturers use PFAS-free coatings derived from plant-based resins to enhance grease resistance, eliminating concerns about chemical migration. Independent testing confirms no residual taste transfer, even after microwaving acidic foods like tomato soup—unlike conventional plastic containers associated with microplastic contamination risks when heated.

Environmental Benefits vs. Real-World Composting Challenges

Lifecycle Analysis: Bagasse vs Plastic and Foam Containers in Carbon Footprint and Waste

When it comes to reducing our carbon footprint, bagasse clamshells are making quite an impact. According to research from Ponemon back in 2023, these eco-friendly alternatives cut down on carbon emissions by nearly two thirds when compared to regular plastic containers. What's even better? They'll break down completely in just about 60 days if composted properly, while traditional foam takes over half a millennium to disappear from the environment. Looking at recent waste audits conducted in 2024, we find that packaging made from sugarcane actually creates 80 percent less waste ending up in landfills than standard materials do. For those concerned about certifications, products that meet EN13432 and ASTM D6400 standards will decompose into mostly organic matter at a rate exceeding 90 percent within three months, making them excellent choices for businesses looking to go green without sacrificing quality or functionality.

The Gap Between Consumer Perception and Actual Composting Infrastructure Availability

A lot of people think when something says "compostable" it will just break down in their backyard, but according to Greenpeace research from 2023, that's not really how things work for most bagasse products. These items actually need special industrial composting facilities running around 60 degrees Celsius to properly decompose. The problem? Less than half (about 35%) of all U.S. counties even have municipal composting programs available. As a result, roughly two thirds of what should be environmentally friendly packaging winds up sitting in regular landfills instead. And there's another catch too. When just one single non-compostable item gets mixed into a batch of 100 compostables, the whole thing becomes contaminated. That kind of contamination completely negates whatever green benefits those properly labeled packages might otherwise provide.

Adoption Feasibility for Fast Food Chains: Cost, Supply, and Case Studies

Leading Fast Food Brands Switching to Bagasse Biodegradable Clamshell Packaging

More than a quarter of US quick service restaurants tried out bagasse clamshells last year through various pilot programs, mostly because customers keep asking for greener alternatives. The math doesn't lie though - these plant-based containers cost around 18 to 22 percent more upfront compared to regular EPS foam. But according to the latest QSR Packaging Trends Report from 2024, things get interesting when restaurants order in bulk. Once a restaurant hits about half a million units per month, the price gap shrinks by roughly 40%. Some chains that jumped on board early have seen their customer satisfaction scores go up by about 14 points on average simply by switching to these eco friendly boxes. McDonald's test locations in California noticed this effect firsthand during their summer trial runs.

Scalability and Supply Chain Reliability of Eco-Friendly Packaging Solutions

The ability to scale operations right now faces some real challenges because not many places have access to composting facilities that can handle bagasse. Only about 4 out of 10 major cities across the United States actually have these kinds of processing centers available. On the bright side though, companies have formed solid relationships with sugarcane producers throughout Brazil and parts of India, which keeps their supply chain running smoothly most of the time. The best performing manufacturers report getting their materials delivered on schedule around 99 times out of 100 since early last year. To deal with unpredictable prices in the agricultural market, many businesses sign long term agreements that set maximum prices ahead of time. This helps protect them when crop yields fluctuate from season to season.

Table of Contents

- Industrial Composting Requirements for Bagasse Biodegradable Clamshell Breakdown

- Certifications Matter: EN13432 and ASTM D6400 Compliance for Compostable Food Containers

- Performance with Hot, Greasy, and Moist Fast Foods

- Microwave Safety and Thermal Performance Compared to Plastic

- Environmental Benefits vs. Real-World Composting Challenges

- Adoption Feasibility for Fast Food Chains: Cost, Supply, and Case Studies